United States, 14th Nov 2024, - OurPCB, a prominent name in printed circuit board (PCB) manufacturing, has expanded its production capabilities to include Rigid Flex PCBs, responding to increased demand across sectors requiring durable, versatile, and compact electronic solutions. Known for its expertise in PCB manufacturing and assembly, the company’s new focus on Rigid Flex technology aims to meet the needs of industries such as aerospace, automotive, medical devices, and consumer electronics.

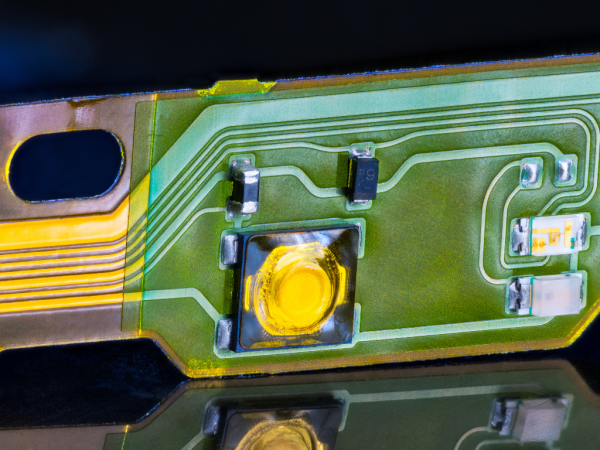

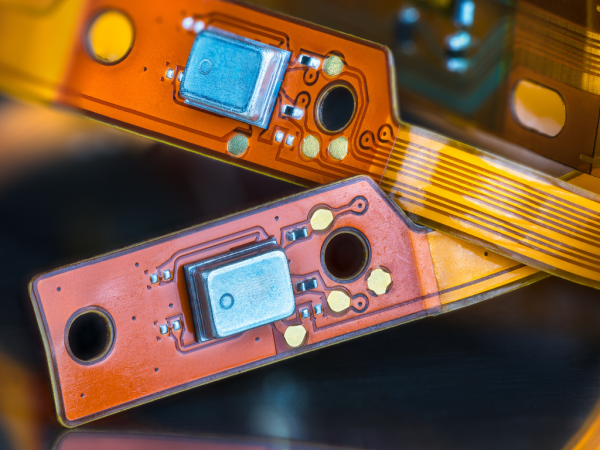

Rigid Flex PCBs combine the structural stability of rigid boards with the adaptability of flexible circuits, allowing for complex designs in compact spaces. As the requirements of modern electronics evolve, these boards offer essential advantages by reducing component weight and saving space, particularly valuable in sectors that demand both high performance and efficient design. The integration of rigid and flexible layers enables a three-dimensional configuration, eliminating the need for connectors and cables, which also minimizes potential points of failure.

Hommer Zhao, Owner of OurPCB, noted the significance of this development: “The decision to expand into Rigid Flex PCB manufacturing aligns with the evolving demands of electronics manufacturing. Rigid Flex technology provides essential design advantages, supporting complex applications with requirements for both flexibility and stability. This expansion reflects a commitment to addressing the industry’s demands for performance and reliability in environments where precision is paramount.”

The introduction of Rigid Flex PCB production is supported by rigorous quality control measures and advanced testing protocols. These standards are crucial in applications where components are subject to extreme environmental conditions, such as in aerospace or critical medical devices. The company’s streamlined production model provides oversight from prototype development through to large-scale manufacturing, enabling consistent quality and precision at each stage.

The shift towards Rigid Flex PCBs has gained momentum, especially as electronic devices become more sophisticated. This technology’s unique capacity to bend and fold makes it an ideal choice for devices where compact configurations are essential, including wearables, medical equipment, and advanced automotive systems. Rigid Flex PCBs address these specific requirements, delivering reliable performance in a variety of challenging environments.

“The outlook for Rigid Flex PCBs suggests continued growth, especially in industries focused on miniaturization and high-density electronic designs,” Zhao stated. “Looking ahead, OurPCB aims to support advancements in PCB technology that anticipate the evolving requirements of modern electronic applications. With an emphasis on quality and adaptability, this expansion sets a foundation for future developments in advanced manufacturing solutions.”

In recent years, the demand for compact, high-performing components has intensified, leading to a rise in interest in Rigid Flex technology. The unique design properties of Rigid Flex PCBs contribute to their appeal in environments where traditional PCBs may not perform as effectively. For applications in aerospace, these boards offer a lightweight, space-efficient solution that meets stringent reliability standards. In the medical field, the durability and flexible design of Rigid Flex PCBs makes them suitable for devices that must perform with absolute precision. As the demand for these solutions increases, companies are prioritizing the development of reliable and efficient manufacturing methods.

OurPCB’s Rigid Flex PCB manufacturing capabilities highlight a broader commitment to delivering adaptable and advanced solutions for modern electronics. By supporting complex design needs, the company strengthens its role as a key player in electronics manufacturing. The expansion into Rigid Flex PCB production not only reflects current trends but also anticipates future advancements, positioning the company as a resource for industries requiring components that balance precision, durability, and efficiency.

For more details about OurPCB’s capabilities as a rigid flex PCB manufacturer, please contact OurPCB directly by phone at +1 626 790 1487 or by email at hommer.z@ourpcb.com.

Organization: OurPCB

Contact person: Hommer Zhao

Website: https://www.ourpcb.com/

Email: hommer.z@ourpcb.com

Contact Number: 16267901487

Country: United States

Release id: 11984

Disclaimer: The views, recommendations, and opinions expressed in this content belong solely to the third-party experts. This site was not involved in the writing and production of this article.